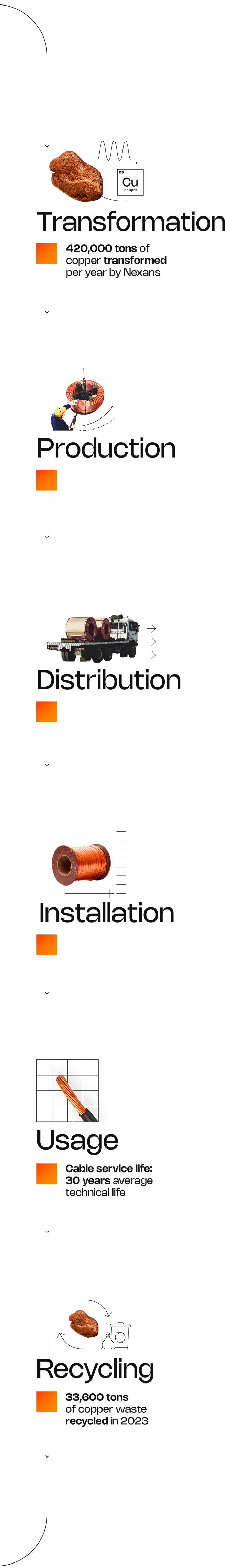

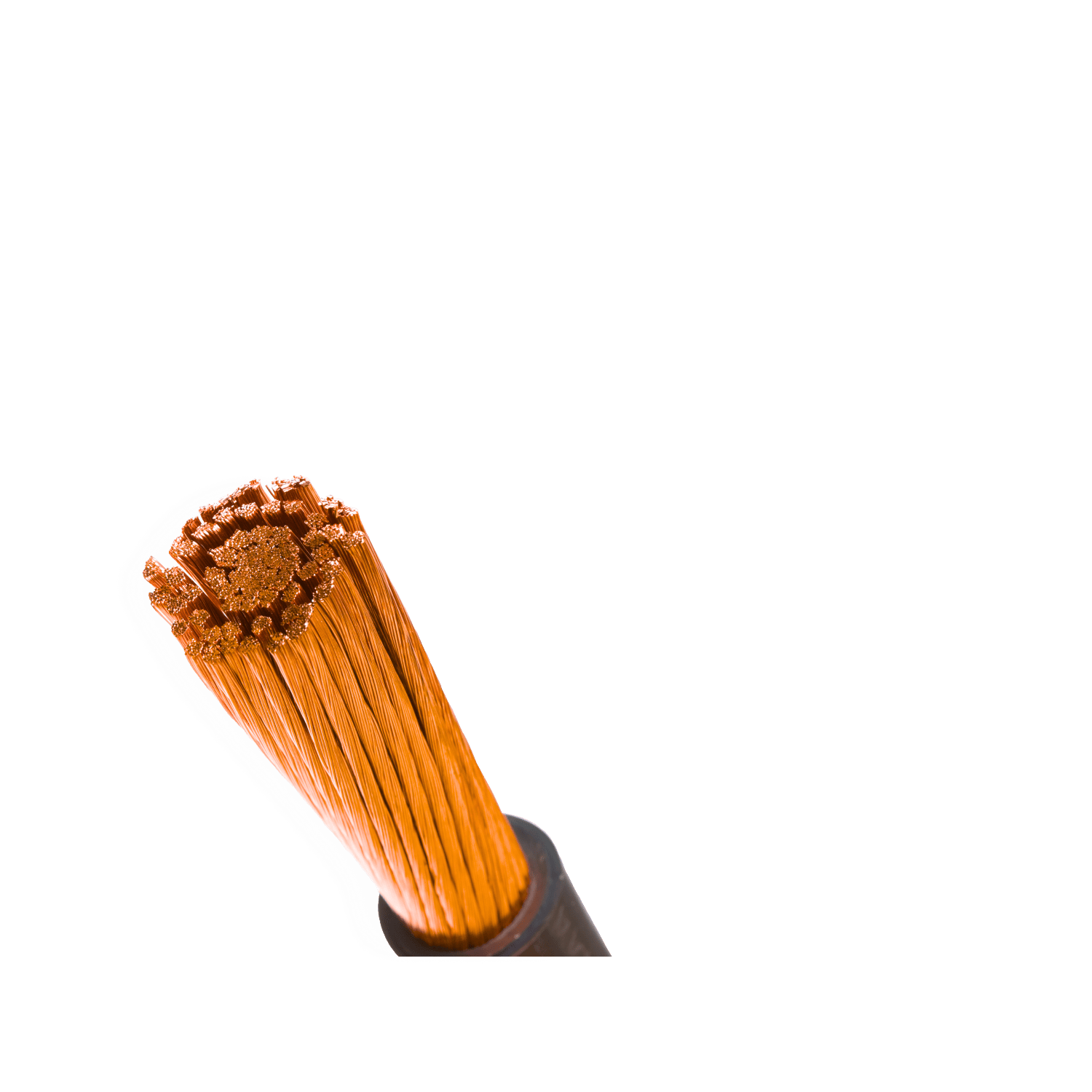

Integrating the metallurgy activity

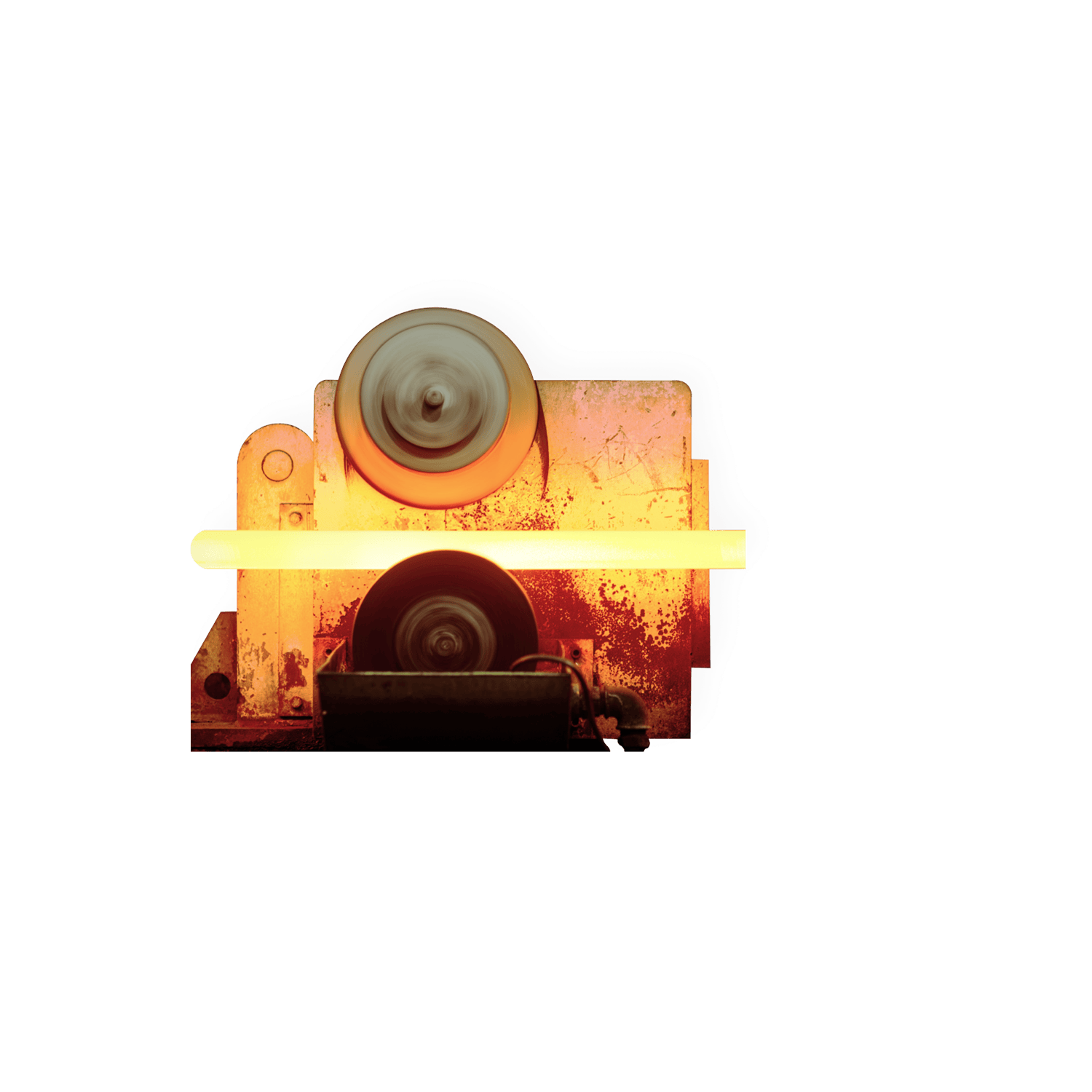

Nexans is the world’s leading vertically integrated manufacturer of cables, with 4 metallurgy plants: Lens (France), Montreal (Canada), Lima (Peru), Santiago (Chile).

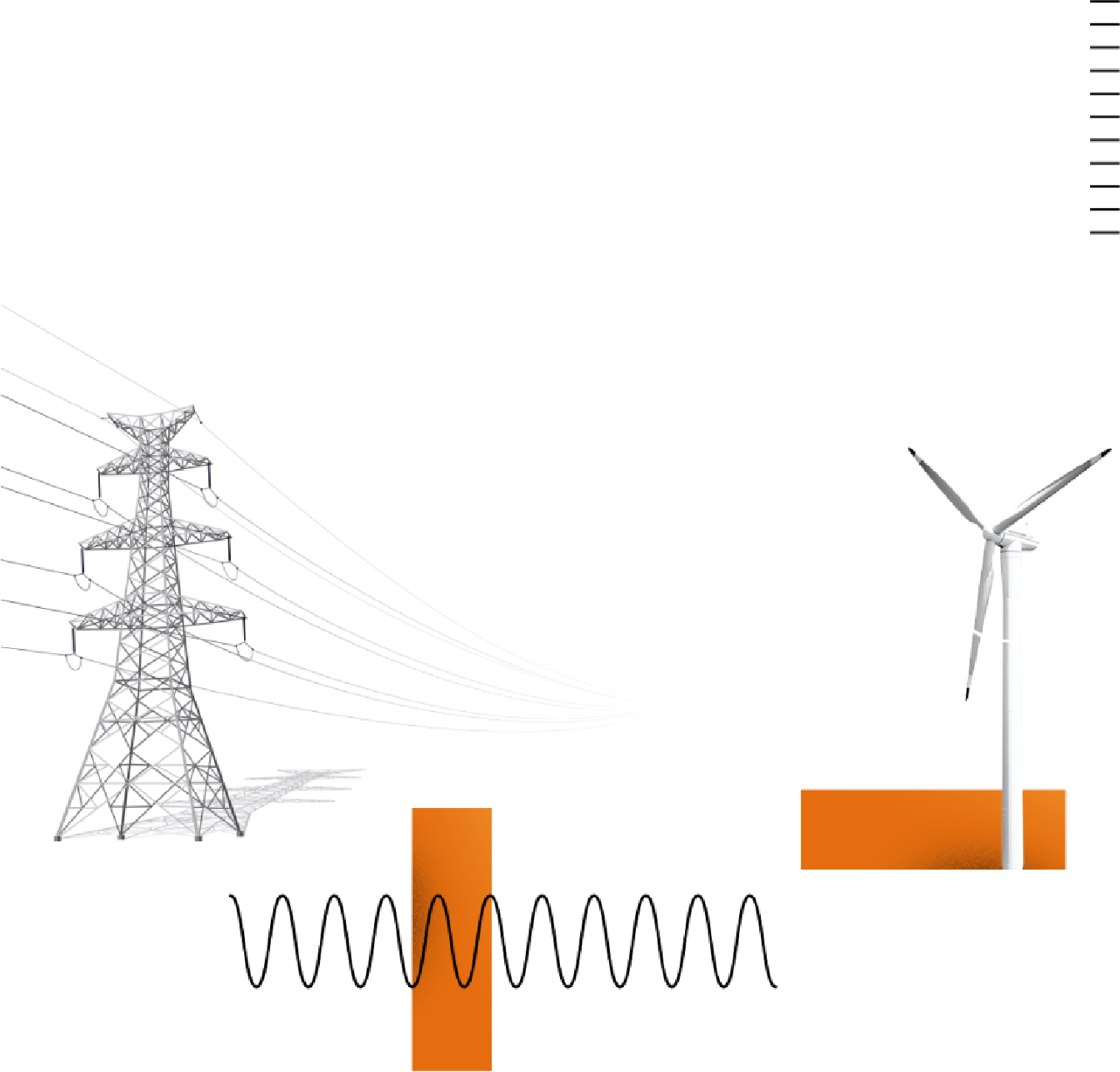

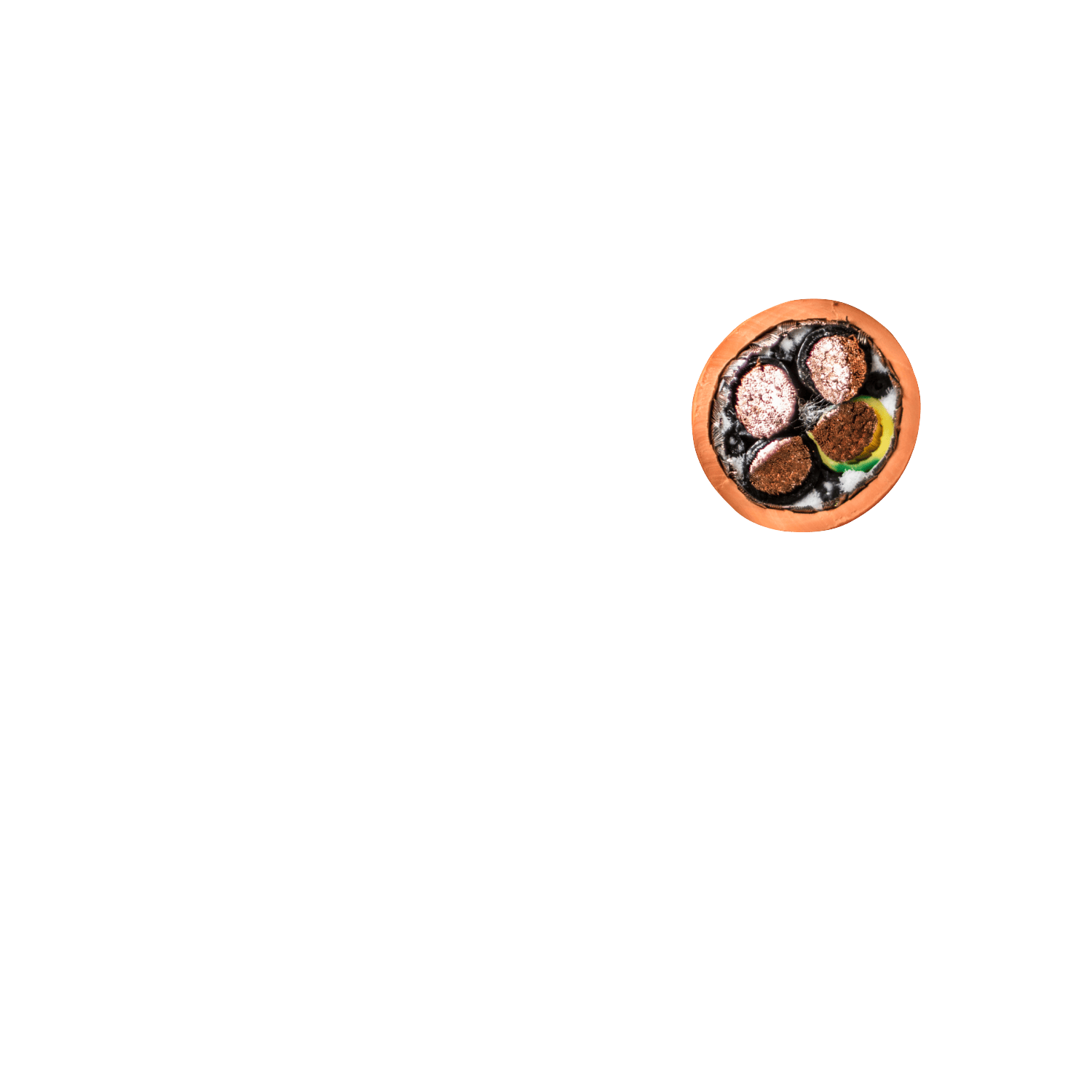

Copper, the first metal worked by man at the dawn of the Neolithic revolution and at the heart of the second industrial energy revolution at the beginning of the 20th century, is today one of the pillars of the ongoing energy transition.

Between increasing shortage of resources and rising global consumption.

The electrical cable industry, which has already undergone many transformations in its long history, is facing a new challenge. At the same time, it is facing an explosion in demand for electricity, and therefore an expected increase in global copper consumption.

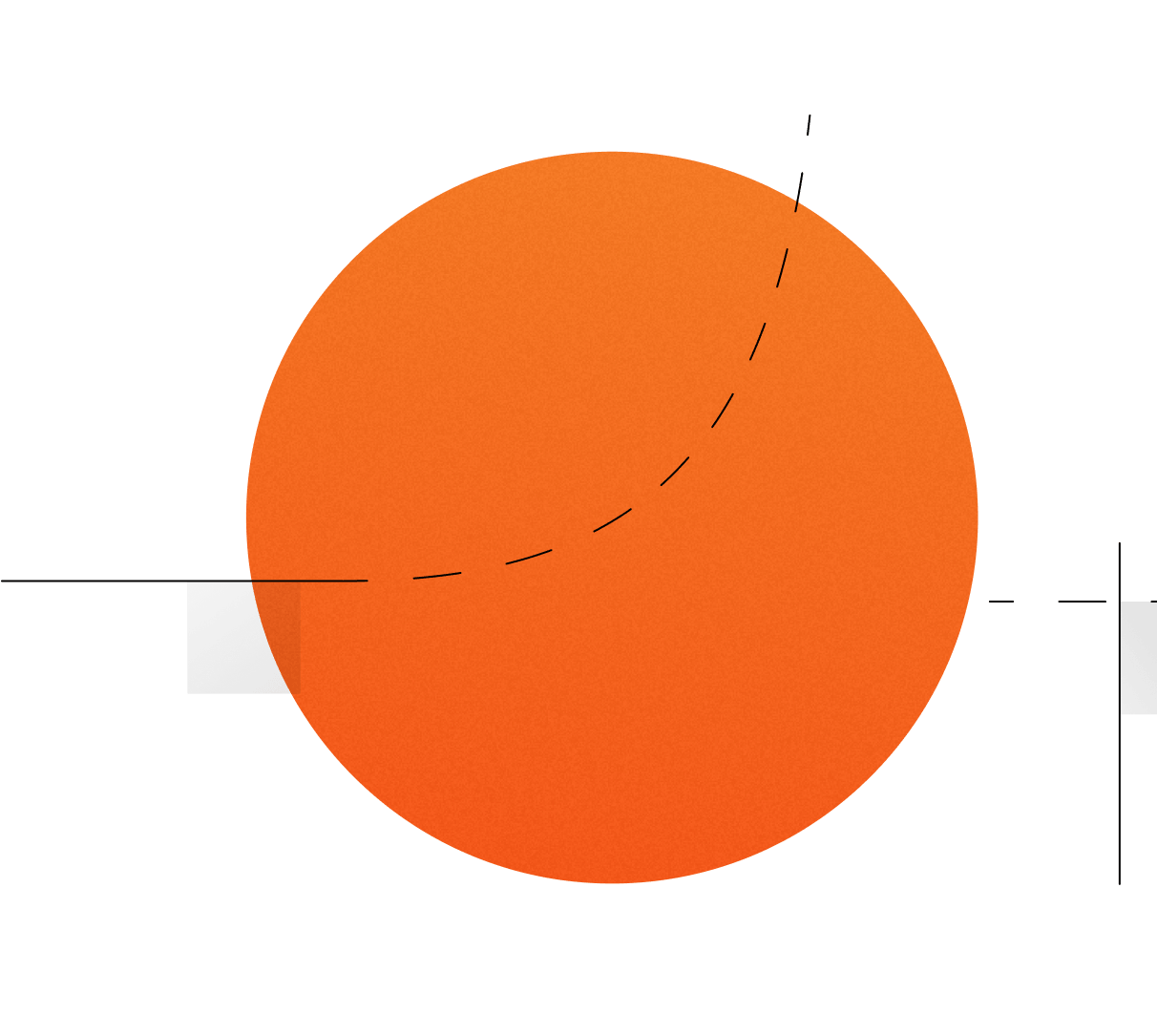

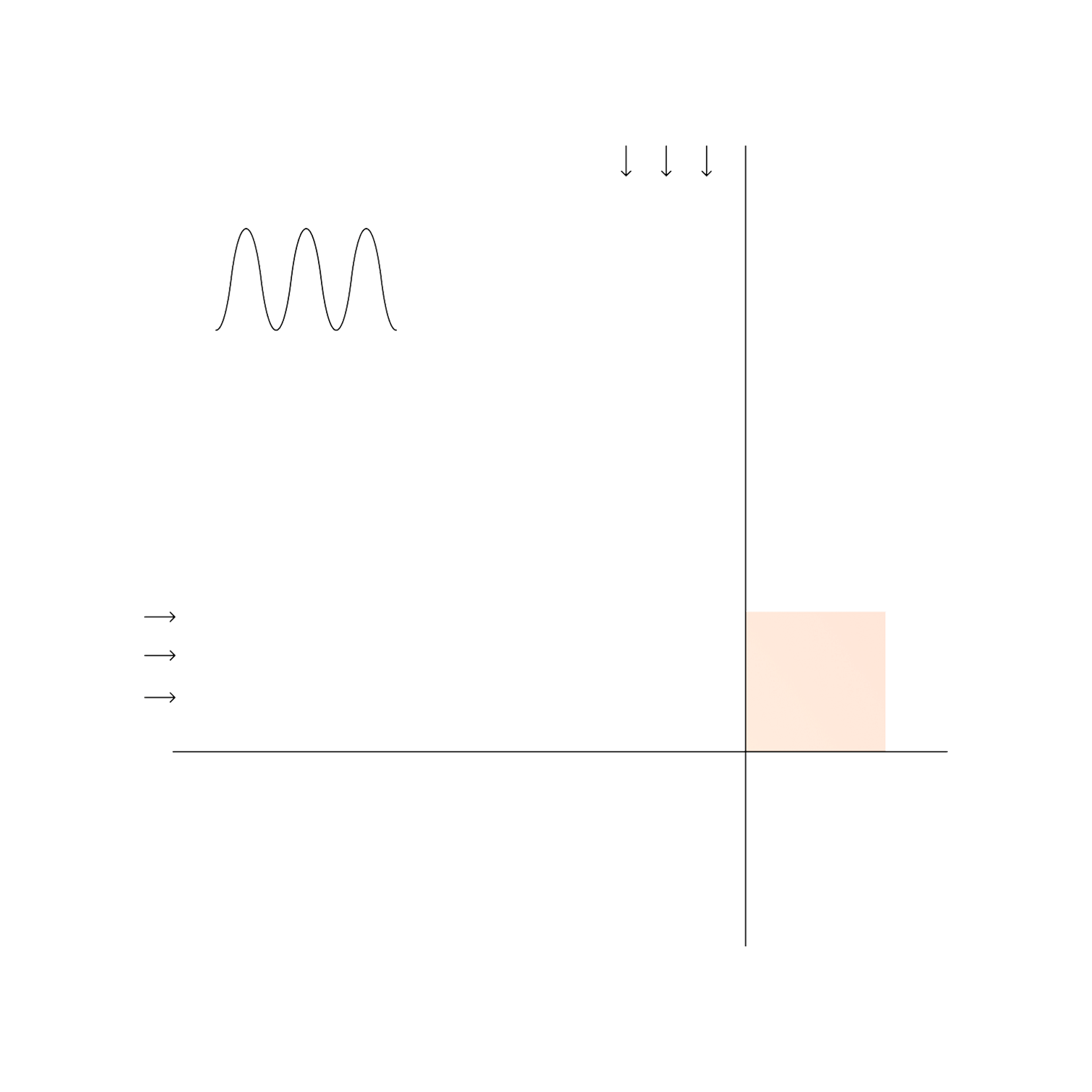

Weight in million tons (Mt)

Sources: Goldman Sachs / ICSG / Nexans Analysis

Annual production of

24Mt of copper and 10Mt of scrap for the next 5 years…

… for a 39Mt annual

copper demand in 2030

Sources: Goldman Sachs / ICSG / Nexans Analysis

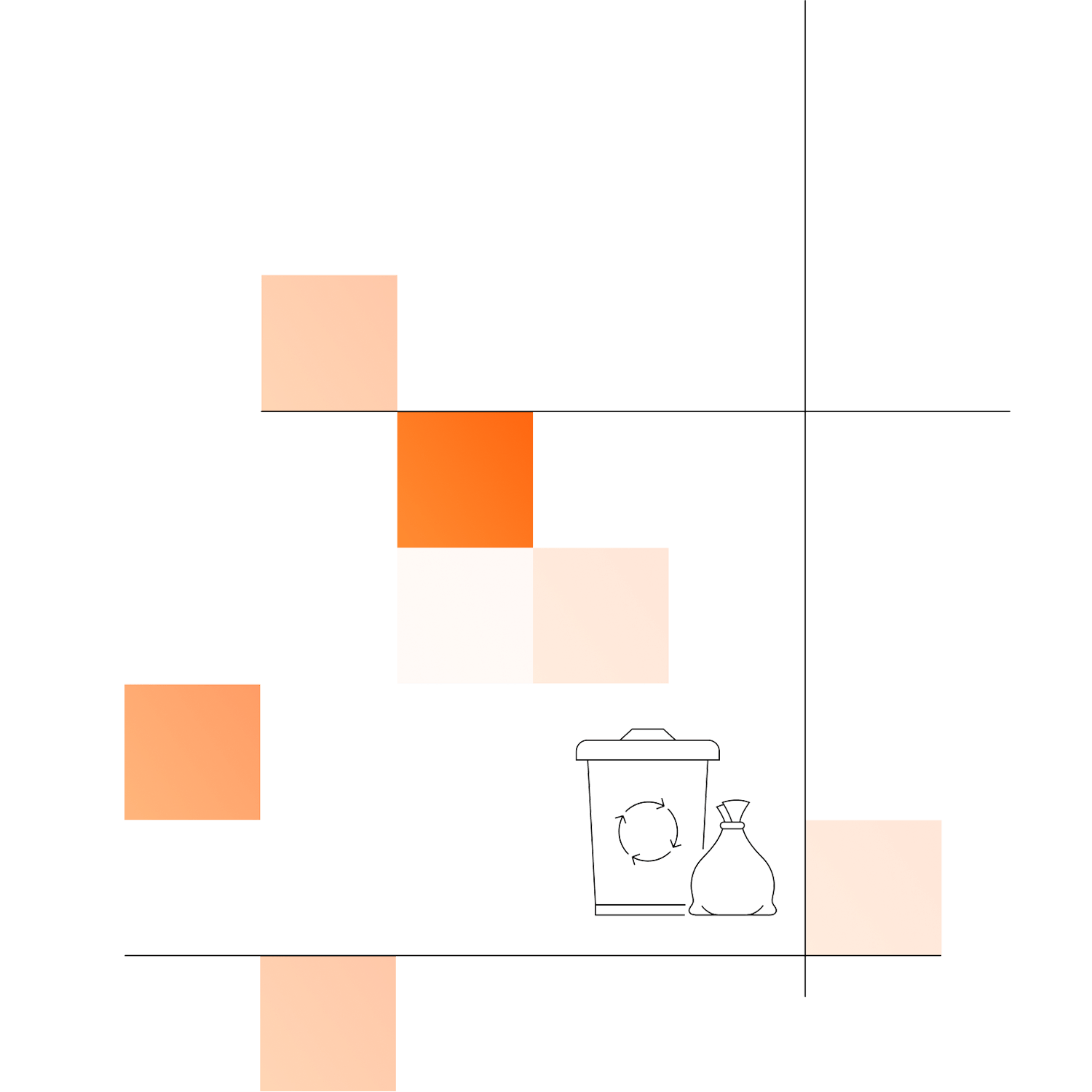

40 to 80%

copper

Sources: Nexans

Nexans is the world’s leading vertically integrated manufacturer of cables, with 4 metallurgy plants: Lens (France), Montreal (Canada), Lima (Peru), Santiago (Chile).

All copper waste undergoes a recycling process.

Improving copper collection from the electrical networks of our cities and infrastructures.

For information

Nexans has been working with RecyCâbles (a joint venture between Nexans and Suez) since 2008. In 2023, 9,410 tons of cable waste have been processed within this facility.

I believe in inventing a new business management model, in which the circular economy will be replaced by circular performance. In other words, an ethical and circular model, but not one that is diminishing.

Christopher Guérin

CEO, Nexans