Industry and industrial technology

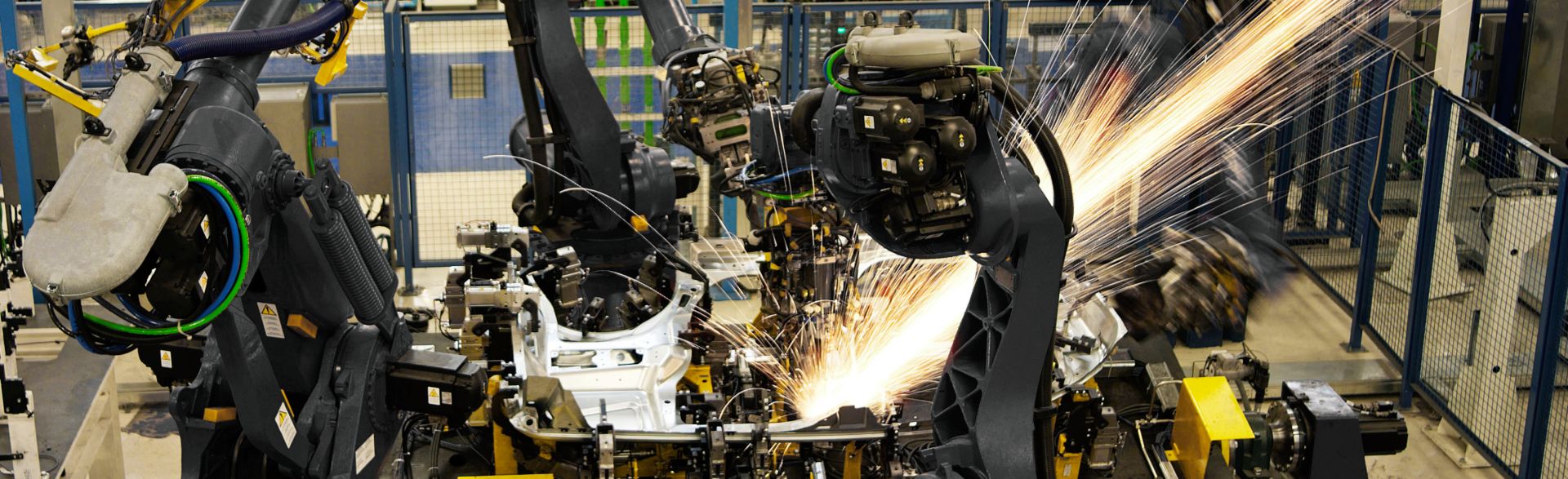

Industry and industrial technology: the age of industry 4.0

Global megatrends such as the energy transition, the mobility revolution and smart infrastructures are creating both opportunities and challenges for OEMs. Nexans is one step ahead. To support OEMs, we are able to deploy solutions integrating the latest technological advancements.

Challenges facing industry and industrial technology

Industry and industrial technology cover a wide range of sectors, including automation, renewable energies, aeronautics and space, railway equipment, oil and gas, and medicine.

OEMs in these sectors are facing the same challenges. The energy transition is forcing them to review their practices and integrate the principles of sustainable development. They need to remain efficient while reducing their carbon footprint and the environmental impact of their activities.

Industry 4.0 is bringing real opportunities for these sectors. New developments in technology will help them to improve their manufacturing practices. However, these developments will also bring new costs, primarily for the acquisition of technology and for workforce training.

The industrial IoT (IIoT) will help to make industry smarter, particularly in terms of response time and decision-making. At the same time, however, it raises a number of challenges, starting with security.

To keep pace with these changes, and to integrate these new technologies, OEMs need cable solutions delivering even higher levels of performance.

Nexans provides customized cabling and interconnection solutions to meet all their power, data and automation needs.

Evidence

- An increase of over 43 billion in the number of IoT-connected devices by 2023 (McKinsey)

- Three major imaging OEMs supplied by Nexans

Design cables for the demanding environment of industrial automation.

Deliver solutions tailored to specific sectors, taking account of their specific constraints and characteristics.

Innovate to supply solutions for the transition to Industry 4.0.

“With the advent of Industry 4.0, it is even more important to keep smart factories running smoothly by transmitting data that are vital for production and process health.”

Andreas Rietz – Global Product Manager

Our objectives

- Keep smart factories running smoothly.

- Make human and environmental safety a key priority.