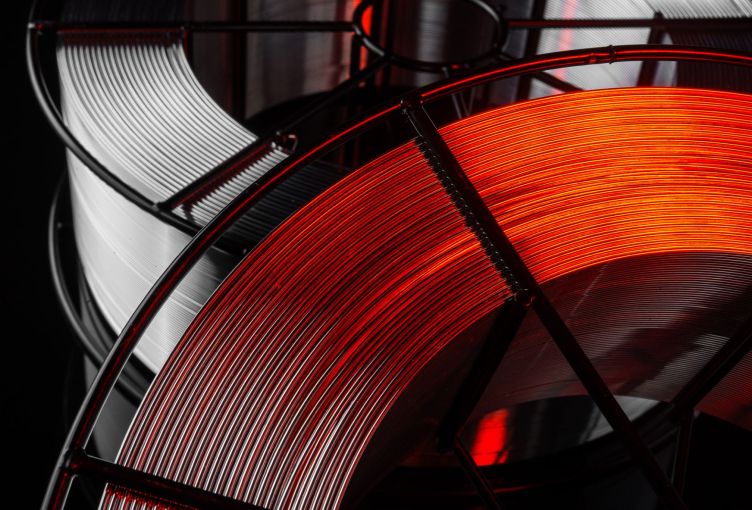

Responsibly produced copper certified by the Copper Mark

In 2023, the Group became one of the first cable manufacturers to receive the Copper Mark, attesting to the copper industry’s contribution to the UN’s Sustainable Development Goals (SDGs). The rigorous Copper Mark assessment process investigates each copper production site to independently verify the application of responsible practices.

Nexans’ metallurgical facilities in Montreal (Canada) and Lens (France) have both been awarded the Copper Mark. They were assessed against a set of 32 internationally accepted sustainability criteria, in line with environmental, social and governance standards. The Group is one of the first cable and wire rod manufacturers and one of the first copper rolling mill operators in North America and Europe to earn this certification. We will shortly be launching the Copper Mark assessment process for our two other mills, in Peru and Chile.

This Copper Mark recognition highlights Nexans’ global leadership in sustainable electrification. As a member of the UN Global Compact since 2008, the Group upholds ten fundamental principles in the areas of human rights, labor practices, environmental protection and anti-corruption. We have also incorporated Sustainable Development Goals (SDGs) into our corporate social responsibility priorities. And in 2023, Nexans pledged to reach net-zero emissions by 2050, in alignment with the Science Based Targets initiative (SBTi).

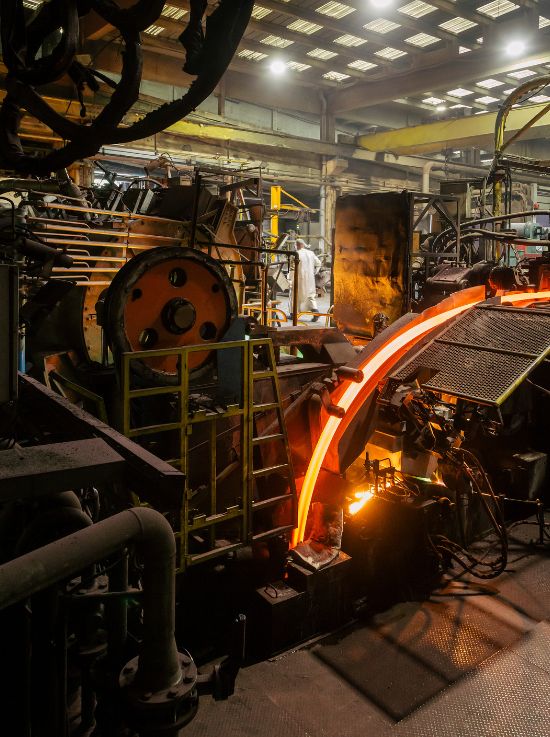

Copper recycling

Nexans is working to increase the amount of recycled copper used in our cables to reduce natural resource consumption and shrink their environmental impact. By vertically integrating scrap metal into copper processing, we can incorporate a significant share of recycled copper into our upstream production. The Group aims to include 30% of recycled content in copper bars produced at the Lens facility by 2030.

In 2024, the Group recycled 90,540 tons of copper in its Lens (France), Montreal (Canada) and Lima (Peru) casting units to produce 43,0215 tons of copper rod, representing a 21.0% share of recycled copper (versus 16.2% in 2023 considering the same calculation methodology).

In other countries, the Group has also undertaken to send metal waste to suppliers for recycling. These suppliers then incorporate the recycled metal into new bars sold to Nexans.

Thanks to this copper recycling capacity, we can reduce our carbon footprint while preserving natural copper resources. However, availability of copper scrap is a crucial prerequisite to increasing the recycling rate. We are working with the Group’s customers to expand the collection of copper scrap.