Subsea interconnections: joining forces to promote the energy transition

The all-electric age is just around the corner. It will involve transmitting more renewable electricity worldwide and ensuring the reliability of power grids. In response to this new reality, the rapid deployment of longer, more efficient interconnections between islands, countries and continents has become a priority. Nexans is contributing to the electrification of tomorrow’s world, drawing upon 120 years of know-how and expertise in the manufacture, installation and project management of subsea cables.

Challenges associated with subsea interconnections

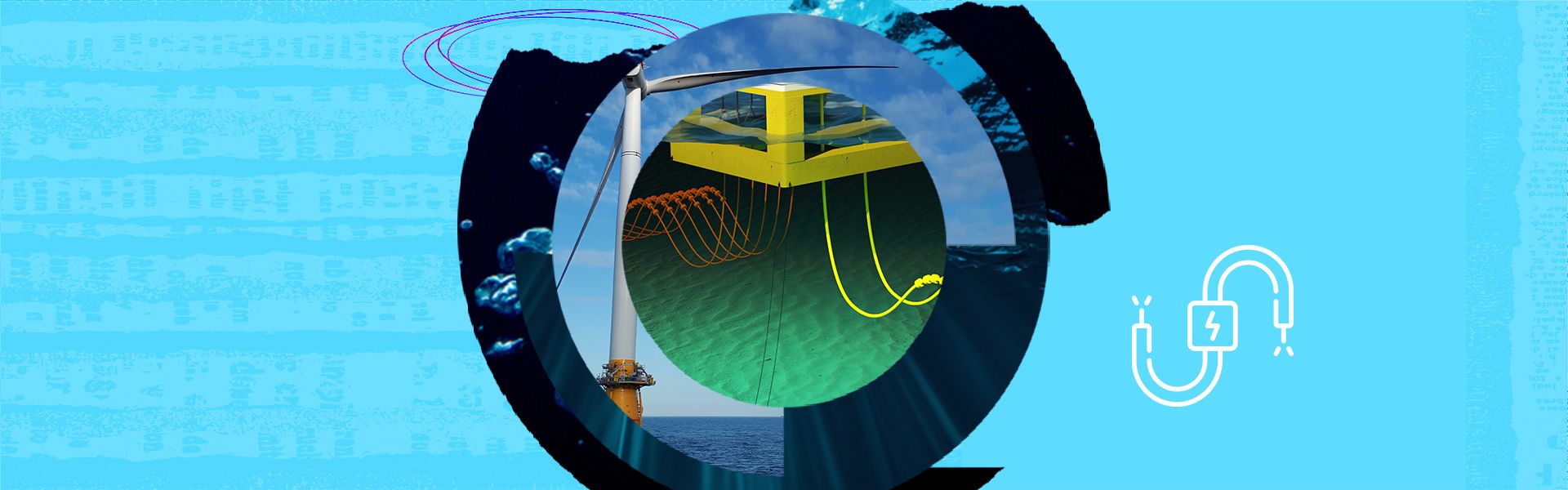

Adding renewable energy capacity worldwide is one of the steps to be taken in building an all-electric, low-carbon future. To achieve this, we need to opt for safe, sustainable solutions, particularly for subsea interconnections.

Managing the additional power from renewable sources involves deploying a significant number of new, advanced interconnections, and making them stable and reliable. To connect regions and countries, these cables must be able to carry more energy over longer distances, and in particular to establish subsea links in order to promote the transfer of renewable electricity between communities.

More specifically, high-voltage direct current (HVDC) interconnections play a strategic role in connecting transnational networks by making it possible to:

- increase connectivity between national power grids and distribute electricity between countries and regions, using, for example, the excess supply in one country to make up for the shortage in another,

- stabilize the electricity supply,

- better integrate the various sources of renewable energy,

- manage the intermittency of renewable energies,

- strengthen energy security,

- reduce failure,

- regulate prices.

Expanding interconnections between countries is a requirement that faces a number of challenges. Installing cables over long distances requires specific expertise, technologies and equipment, particularly cable-laying vessels to ensure the reliability, safety and stability of the network. Few players in the cable industry can meet all these criteria.

At Nexans, our first interconnection project was the Skagerrak subsea link between Denmark and Norway, dating back almost 50 years. Since then, we have undertaken many more projects around the world, enabling us to perfect our knowledge of high-voltage (HV) subsea cable systems and to develop unique know-how. We are involved in a wide range of projects, including creating electricity corridors between countries to strengthen their energy security and independence, while also seeking to make renewable energies more widely available and to balance international supply and demand.