- The Orkney Transmission Link will exchange up to 220MW of energy between the Orkney Islands and the UK mainland

- There will be one high voltage alternating current (HVAC) cable circuit extending approx 69km in route (53km subsea, 15km land) from Finstown in Orkney to Dounreay in Caithness

- The significant contract includes both the production and the installation of the cable

Nexans, a global leader in the design and manufacturing of cabling systems and services, has signed the contract for the Orkney Link by SSEN Transmission following the capacity reservation agreement signed in November 2023. The significant contract includes both the production and the installation of the cable. The 220kV high voltage alternating current (HVAC) cable will be largest capacity cable connecting the Orkney Islands to mainland Scotland and will span 53 km offshore and 16 km onshore route in total in Finstown, Orkney and Dounreay in Caithness, UK.

The Orkney Link will exchange up to 220 MW of renewable energy between the islands and the mainland and is a critical step in strengthening the UK power network, supplying demand centres in the North of Scotland and beyond with clean energy from one of the world’s greatest resources of renewable electricity. Subsea interconnectors, which connect two areas of land together with an underwater electrical cable, allow for the expansion of electrification and the growth of renewable energy. In the case of the Orkney Islands, there is an abundance of renewable resources from established and planned onshore wind farms to emergent technologies that harness electrical energy from the oceans and will all support delivery of the UK and Scotland’s Net Zero targets.

We are looking forward to working on the Orkney Link as it represents a major milestone in connecting remote renewable energy resources to the UK mainland. Subsea interconnectors are critical for reliably delivering electricity across the oceans from the places with the greatest supply to those with the greatest demand, thereby increasing network resilience and allowing access to reliable energy for consumers.

EVP Generation and Transmission Business Group, Nexans

We’re delighted to have awarded these crucial contracts to Siemens-BAM JV, Nexans and RJ McLeod for the delivery of the Orkney connection project. All three have a strong track-record of delivering challenging projects and we’re looking forward to continuing our relationship with them.

Deputy Project Director, SSEN Transmission

The interconnector will be manufactured at Nexans’ plants in Halden Norway for the offshore sections, Charleroi, Belgium for the onshore cable sections, and Cortaillod in Switzerland for the accessories. Nexans will also install the cable using its state-of-the-art cable laying vessels. The project will be delivered in 2027 by Nexans experts at multiple locations, including in the UK and adds to Nexans’ expanding portfolio of interconnectors including the Celtic Interconnector and the Crete-Attica Interconnector.

Find all our press releases

Read all- Nexans invests 90 million euros in its facilities in Charleroi, Belgium, Erembodegem, Belgium and Calais, France to support the growth of offshore wind and subsea interconnections.

- The investment will include the construction of a new, 53 meter tower for the insulation of onshore cables at Nexans’ plant in Charleroi, Belgium, and will allow for the production of 525kV onshore cables necessary to support the TenneT frame agreement.

- Nexans is committed to a long-term strategy of electrification made possible only through the support of renewable sources of energy.

Nexans announces plans to invest 90 million euros to support the growth of offshore wind in Europe. The investment will include the construction of a new, 53 meter tower for the insulation of onshore cables at Nexans’ plant in Charleroi, Belgium and will allow for the production of 3,000 mm2 525kV HVDC onshore cables necessary to support TenneT’s three grid projects, BalWin 3, LanWin 4, and Lanwin 2 under the frame agreement signed last year.

Nexans is committed to a long-term strategy of electrification made possible only through the support of renewable sources of energy. This investment will enable Nexans to fulfill this vision and drive the next electrical revolution forward.

The investment will also include upgrades to the cable manufacturing process such as a new stranding line and a degassing system specifically designed for HVDC cables and a new aluminum drawing line to increase our volume of aluminum wire production. While the majority of the investment will be directed at upgrading its manufacturing plant in Charleroi, Nexans’ other facilities will also get a boost including a new HVDC lab with a hall specifically built for 525kV HVDC testing at its Calais facility in France, and a new injection press at its power accessories facility in collaboration with teams in Erembodegem, Belgium. The investment will begin in 2025 and run through 2026 when the work is completed.

The Charleroi plant will also connect to the La Sambre channel which will allow Nexans to reduce transportation CO2 emissions by 85%. The city of Charleroi has already begun a project to establish a multimodal transportation platform in this area.

We are pleased to announce this new investment reinforcing our position as a leader in the energy transition. The ability to produce land cables up to 525kV is a game changing capability that will enable us to drive the transition forward for years to come. We are looking forward to completing this critical upgrade in our infrastructure to keep pace with the ever-increasing electricity demand globally.

EVP of Generation and Transmission Business Group, Nexans

All our press releases

Read all- The 4th edition of the Group’s annual Climate Day will focus on the theme: “Sustainable Electrification for the Energy Transition: A Major Opportunity for Africa.”

- This event will bring together key stakeholders from the energy sector, including institutions and economic players, with significant participation from African countries.

- A unique opportunity to engage in high-level discussions and to showcase concrete solutions for climate challenges in the region.

Nexans, a leader in the design and manufacture of cable systems and services, is organizing the 4th edition of its “Climate Day” in Morocco, in partnership with the Ministry of Industry and Trade, the Ministry of Energy Transition and Sustainable Development of Morocco, and the Cluster ENR. Initially scheduled for September 2023, the event was postponed due to the tragic earthquake in Morocco and will now take place in Rabat on September 26, 2024. This annual gathering continues the tradition of previous editions held in New York, Paris, and Stockholm.

This summit will bring together key players from the energy sector and ecosystem experts to raise awareness of climate challenges, share experiences, and propose concrete solutions for sustainable electrification. High-profile institutional figures will also be invited to speak.

Under the theme “Sustainable Electrification for the Energy Transition: A Real Opportunity for Africa”, this edition aims to strengthen the debate on climate issues in Africa. It will strive to place sustainable development at the heart of the continent’s economic and social interests. By fostering investment opportunities in renewable energies, the event seeks to bring forth concrete solutions to support the energy transition. Nexans’ Climate Day aspires to be a dynamic summit where ideas and initiatives converge for a significant impact on Africa’s energy future.

We are honoured to host the Climate Day in Morocco, a country that, under the visionary leadership of His Majesty King Mohammed VI, stands out for its remarkable efforts in accelerating the energy transition and promoting sustainable development. Morocco is an inspiring example for Africa and the world, demonstrating that economic growth can go hand in hand with the protection of our planet.

General Manager, Nexans North & West Africa

Morocco perfectly embodies the values of energy transition and sustainable development that we advocate, which is why we chose it as the host country of the 4th edition of our Climate Day. In a world facing ongoing crises and resource scarcity, companies have a crucial guiding role. We are therefore enthusiastic about bringing together decision-makers, experts, and renowned entrepreneurs at this event to contribute to accelerating the implementation of concrete solutions in Africa and beyond.

CEO, Nexans

The event will also be an opportunity to reward the winners of the Nexans Climate Challenge, a competition designed to encourage climate innovation by recognizing the most promising projects in this field.

All our press releases

Read all our press releases- Nexans invests 15 million euros in its historical plant in Bourg-en-Bresse to increase its production of low-carbon medium-voltage cables, in order to support growth in electrification requirements in France and in Western Europe.

- The project involves installing two new latest-generation production lines and modernizing the entire manufacturing flow, and will roll out from H1 2025 to H1 2026.

- The Group is thus stepping up its capacity to manufacture EDRMAX® direct-buried cables, which are simpler to lay and reduce the system’s carbon footprint.

Nexans announces plans to invest 15 million euros in its production plant in Bourg-en-Bresse, Auvergne-Rhône-Alpes (east-central France). The investment will increase the plant’s medium-voltage cable production capacity with a view to supporting distribution grid operators and installers, and to supplying renewable energy projects, including solar and wind farms, in France and in Western Europe.

At a time when demand for electricity is booming and the challenges around it are becoming increasingly crucial, Nexans confirms its role as a prominent partner for the stakeholders in Europe’s electricity distribution systems.

The investment, which will be made from 2024 to 2026 will notably involve installing a new stranding machine that can produce new, larger aluminum cable sections, including 400 mm² ones. Nexans will also invest in a new XLPE triple extruder with the best technology in its class. All these machines will be up and running in H1 2026.

Meanwhile, the Group will modernize part of its industrial capacity, in particular the sheathing and assembly lines, to enhance employee safety and plant productivity. With these upgrades, Nexans also plans to strengthen its production of EDRMAX® reinforced direct-buried cables1, which have been proven to simplify laying processes, reduce costs and minimize carbon footprints.

The workshops will also be equipped with cutting-edge digital tools to improve controls’ quality and enhance employees’ experience. Modernizing its processes will turn the Bourg-en-Bresse plant into a 4.0 digital factory geared for sustainable, local production and make it particularly attractive to young talents.

We are very proud to announce this major investment by Nexans in its historical Bourg-en-Bresse plant. Besides maintaining our high standards of safety for our employees and of quality of service for our customers, this new ultramodern production equipment will enable us to better meet evolving demand from the big players in the energy sector. Lastly, modernizing the plant will enable us to offer them even more high-performance, low-emission cables.

Vice-President Power Distribution Cables & Accessories, Nexans

All our press releases

Read all- Nexans and SNCF Réseau are once again joining forces in superconductivity to increase the safety and reliability of the rail network.

- Developed by Nexans and installed by SNCF Réseau, the superconducting fault current limiter (SFCL) is a world first on the rail market. It limits disruptions to the power supply of the rail network using a standalone system to reduce short-circuit currents.

- Designed to supply power for trains in the Belfort area (Burgundy-Franche-Comté region in France), this innovative limiter improves the availability of electrical installations.

Nexans, a leader in the design and manufacture of cable systems and services, is forming a unique partnership with SNCF Réseau, infrastructure manager of the French rail network, to deploy a superconducting fault current limiter. This technological innovation will secure and optimize electric rail traction on the line between Belfort and Delle, including the cross-border link with Switzerland.

A revolutionary solution for a more efficient rail network

Railway power grids are under growing pressure, with the continuing expansion of rail traffic and the upgrades to equipment. Power surges and short-circuits can cause major disruptions. To address this challenge, Nexans and SNCF Réseau have joined forces to deploy an innovative superconducting current limiter (SFCL).

Developed by Nexans, and integrated with the Bussurel substation, a strategic location identified by SNCF Réseau, the SFCL is able to reduce short-circuit currents in standalone mode, regenerating in less than five minutes, without human intervention.

This revolutionary technology offers several advantages:

- Improved network reliability and safety. The SFCL acts as a shock absorber in the event of a problem, limiting current peaks and disruptions to the network when short circuits occur.

- Optimized infrastructures. In the long term, the SFCL could pave the way for smaller electric traction installations, thereby cutting rail infrastructure costs, while supplying power for more trains.

- Better service. The SFCL avoids the need for rail works that are inconvenient for users, providing an efficient, cost-effective solution with no impact on the traffic schedule.

A partnership to support the energy transition in rail transport

Faced with the need to modernize power grids and meet growing demands for energy, Nexans is positioning itself as a leader in the development of revolutionary superconductor technologies. These innovations will completely transform the electrification of transport and power distribution, paving the way for a more sustainable, high-performance energy future.

Nexans’ vision is based on a network of interconnected superconductor systems, able to meet tomorrow’s energy challenges. This ambition is reflected in iconic projects such as the superconducting fault current limiter deployed on the Belfort-Delle line, a milestone in the collaboration between the two players, as well as the SuperRail project, to power the Montparnasse-Vouillé substation with superconducting cables. These partnerships illustrate the commitment made by the two players to innovation and sustainable development.

We are proud to be working with SNCF Réseau on deploying this innovative solution to the rail industry. The fault current limiter developed by Nexans reflects our ongoing commitment to addressing technological challenges and contributing to the safety and reliability of the power grid. Every day, Nexans’ innovation teams take up the challenge of sustainable electrification, developing innovative solutions to support the growth of rail traffic.

Corporate Vice President, Innovation, Services and Growth, Nexans

This project is part of the innovation strategy implemented by SNCF Réseau to make rail transport more efficient and more sustainable. Through this partnership with Nexans, we are able to implement cutting-edge technological solutions for the benefit of our customers and the environment.

Superconductor Technology Manager, SNCF Réseau

Deployment of the superconducting fault current limiter is scheduled for late 2025. This project is a major step forward in rail electrification, paving the way for further innovations to make transport safer, more reliable and more sustainable.

All our press releases

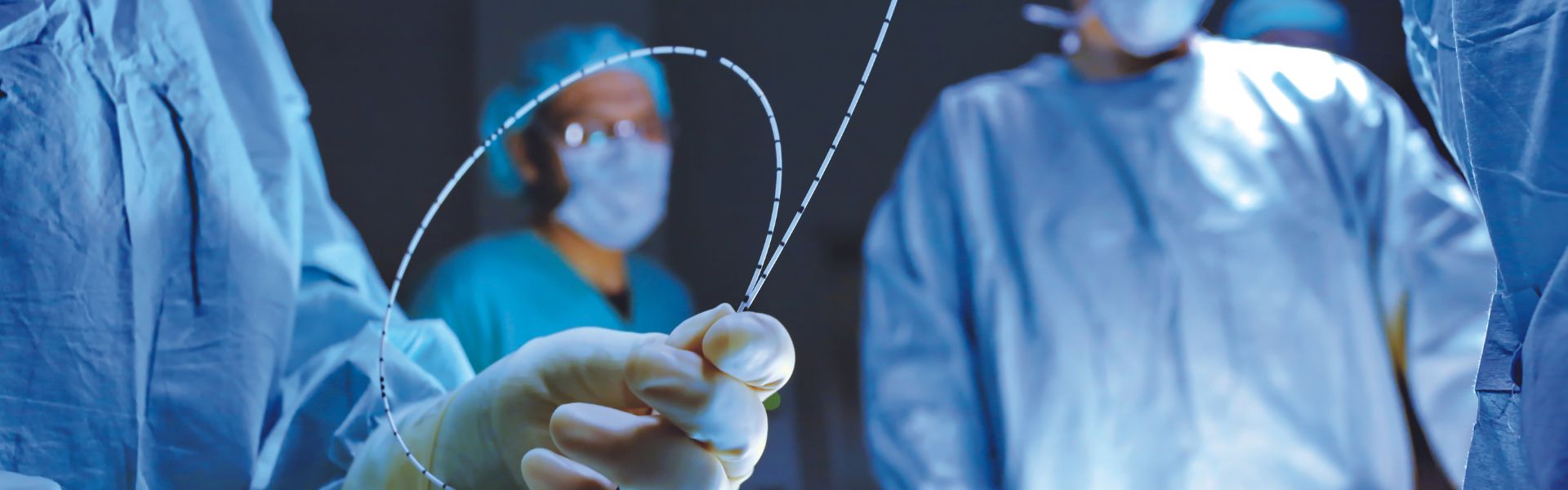

Read all- Nexans is investing €4.5 million in its Draveil site to double production capacity of medical cables in response to growing demand.

- The NEWSENSE® micro-cables will be produced by machines entirely designed and manufactured by Nexans.

- Building on the expertise and know-how of the Draveil workforce, the Group is developing its cable offering dedicated to minimally invasive surgical technologies, pushing the limits of miniaturization.

A leading designer and manufacturer of cable systems and services, Nexans has announced a €4.5 million investment in its Draveil site outside Paris to double its production capacity for medical cables.

With this investment, Nexans will be able to meet growing demand for medical micro-cables used in invasive surgery, a fast-growing market expected to achieve annual growth of 5% a year over the next five years. These cables are used in particular for transcatheter technology and cardiovascular electrophysiology, as well as for monitoring sensors and endoscopy cable solutions.

Through this investment, Nexans will be able to develop its NEWSENSE range of medical cables in a new workshop expanding the existing facilities at the Draveil site. The Group is reaffirming its commitment to manufacturing in France, particularly for products requiring a high level of expertise, as it is the case in the medical field.

These cables meet the most stringent quality standards and will be manufactured on machines specially designed and built by the engineering teams at Nexans Draveil, as they seek to continuously push back the limits of miniaturization. As these machines do not yet exist on the market, they wil further sharpen the competitive edge of Nexans, allowing it to consolidate its position as an industrial leader in cutting-edge technologies.

Consolidating our medical business is one of the strategic development goals set for our Aerospace & Medical division. Our high-performance cables are particularly well suited to environments demanding compliance with standards ISO 13485 (medical) and EN 9100 (aerospace) for safety and reliability. These particularly demanding standards are recognised by our customers worldwide.

Vice President Aerospace & Medical, Nexans

Delivering the speed and efficiency necessary to stay competitive in this niche market, these machines also meet the highest standards of reliability and quality, with the use of optical control technology to inspect the cables on the production line.

With this investment, Nexans will be able to develop its offering for medical OEMs, a field in which the company has over 30 years’ experience. With a dedicated plant and laboratory, Nexans is setting the standard in the supply of micro-cables for devices used in medical exploration as well as in diagnosis and treatment, greatly improving comfort for both healthcare professionals and patients alike.

With this investment, we are strengthening our position in the medical cable market and taking production capacity to a new level, with our machines and technology we push the limits of miniaturization. We are particularly pleased to be making this investment in Draveil, allowing us to expand with a new workshop dedicated to this market segment.

Executive Vice President Industrial Solutions & Projects, Nexans

- Nexans has taken a significant leap forward in its electrification strategy by completing the acquisition of the iconic Italian company La Triveneta Cavi, with recognized excellence in the European medium- and low-voltage cable segments.

- La Triveneta Cavi boasts 700 skilled employees across 4 production units and generates over 800 million euros in sales.

- Nexans, with its proven track record of integrating new players, is poised to accelerate La Triveneta Cavi’s growth in key sectors such as building wire, fire-resistant cables, and renewable energy solutions.

Nexans, a leader in the global energy transition, today announces the completion of its acquisition of La Triveneta Cavi, one of the European leader in medium- and low-voltage cables. The acquisition is a significant leap forward in Nexans’ strategy to become an electrification pure player. La Triveneta Cavi brings a rich heritage of innovation, cutting edge manufacturing and logistics and a seasoned management team to further accelerate Nexans’ value creation in electrification.

Based in Italy since 1965, La Triveneta Cavi primarily manufactures low-voltage cables for building, infrastructure, fire-retardant cable systems and renewable energy applications across 30 countries. The company operates a best-in-class, vertically integrated network with three cable production units featuring highly efficient logistic capabilities, in addition to a world class “in-house” copper drawing facility. The company boasts a workforce of approximately 700 skilled employees and has generated current revenues of more than 800 million euros over the last twelve months.

The enterprise value of around 520 million euros represents a multiple of 5.6x 2023 EBITDA pre-synergies and 4.6x post run rate synergies. It will be high-single-digit accretive to earnings per share (EPS) from year one. Nexans’ financing of the acquisition will have limited impact on run rate leverage to remain ≤1.0x.

The acquisition of La Triveneta Cavi is fully in line with our vision of Nexans as a global electrification pure player. This move significantly strengthens our presence in the electrification segment, where we have successfully completed two acquisitions over the past two years and it will further enable the acceleration of new sustainable offer launches in high-demand sectors. Last but not least, I cannot be more delighted to welcome the talented people of La Trivineta Cavi to the Nexans family.

CEO, Nexans

All our press releases

Read all- Nexans has officially opened the newly expanded section of its high voltage subsea cable plant in Halden, Norway to support the increased demand globally for electrification and the energy transition.

- Nexans’ investment created more than 100 jobs and will be able to deliver 525kV HVDC and 420kV HVAC subsea cables.

- The plant incorporates the most advanced cable production technology to date and features a second extrusion tower which will allow the plant to insulate four cables simultaneously in addition to the two existing lines – the tallest building in Norway and the country’s first skyscraper.

- The Halden plant also celebrates its 50th anniversary, marking a key milestone in Nexans’ 109 year history in Norway.

Nexans, a leader in the world’s transition to a more connected and sustainable future has officially opened its newly expanded section of its high voltage subsea cable plant in Halden, Norway to support the increased demand globally for electrification and the energy transition. The expansion project will support key projects including Nexans’ frame agreement with TenneT signed last year.

The construction for the expansion of the plant began in November 2021 and incorporates some of the most advanced cable production technology which will be able to deliver subsea cables up to 525kV for High Voltage Direct Current (HVDC) and 420kV for High Voltage Alternating Current (HVAC). The 34,000 square meter expansion more than doubles the capacity of the plant for HVDC extruded cables. It also features a 152.89 meter tall second extrusion tower which will allow the plant to insulate four cables simultaneously in addition to the two existing lines and qualifies as Norway’s tallest building and first skyscraper. The tower will be focused on the production of HVDC cables for offshore wind farms, but can serve both HVDC and HVAC applications. 100 more people have been hired and trained to support the increase in production from the facility and local indirect jobs will also be created to support the supply chain in Europe and globally. This brings the total employment of the plant up to around 1,000 employees on site.

The Halden plant also celebrates its 50th anniversary. Having been originally built in 1974 to support the Skagerrak 1 and 2 interconnector projects in cooperation with Statnett, the facility has been involved in projects across the globe. The first extrusion tower was built in 1992 to incorporate the first high voltage XLPE insulated cables into Nexans’ portfolio. The plant also features a state-of-the-art testing facility for high voltage components as well as its own slip to load cables directly onto cable laying vessels such as Nexans’ CLV Aurora, C/S Skagerrak, and Nexans’ newest vessel under construction, the CLV Electra.

Our investment in Halden significantly increases our production capacity and illustrates Nexans’ commitment to sustainability and the global energy transition. The plant will supply international markets with cables for key offshore wind farms and interconnectors that will bring renewable energy from the areas of high supply to those of high demand.

CEO, Nexans

The importance of the newly expanded Halden plant cannot be overstated. In a world that is rapidly becoming more electrified, the expansion of cable production will supply a critical need in Europe and globally. We are excited to work with our customers on producing the most technologically advanced cables to date, which will connect renewables to shore and electricity across continents.

EVP of Generation and Transmission Business Group, Nexans

All our press releases

Read allNexans announces today the success of a bond issuance in an aggregate principal amount of €575 million with a 5-year maturity and an annual interest rate of 4.125%.

Nexans has taken a significant leap forward with this bond issuance, which will be used to finance the acquisition subject to regulatory approvals from the relevant authorities announced in February 2024 of La Triveneta Cavi, an iconic player in the European medium- and low-voltage cable segments, and/or for general corporate purposes of the Group.

Nexans seized the opportunity offered by an active and favourable market environment and the transaction has been welcomed by institutional fixed income investors in France and abroad, confirming the market’s confidence in the Group’s credit quality.

The success of this new bond issuance, the largest bond issuance by Nexans, confirms debt capital market confidence in the Group’s electrification Pure Player strategy.

Deputy CEO and CFO, Nexans

The bonds are rated BB+ by Standard & Poor’s and are admitted to trading on the regulated market of Euronext in Paris as from its issue date.

More about Nexans bond issuance

Debt and Credit rating

More information- Nexans and energy company Equinor strengthen their long-term collaboration with a four-year contingency and preparedness contract.

- Nexans’ unique and extensive repair expertise covers all types of existing cables

- The contract includes assistance from a team of Nexans experts and the provision of a vessel to meet the intervention requirements.

Nexans has signed a contingency and prepardness contract with international energy company Equinor.

As an international energy group committed to creating long-term value for a low-carbon future. Equinor has a long-standing relationship with Nexans which has resulted in a number of pioneering projects.

Nexans is extending this collaboration through a 4-year agreement that includes turnkey repair services for various cable systems. Equinor will manage and operate the contract on behalf of the Pipeline Repair and Subsea Intervention (PRSI) Pool members. The agreement covers approximately 3,000 km of cable.

To ensure Equinor’s assets’ normal functioning, Nexans will provide its unique expertise of performing complex turnkey repairs on all types of cables (XLPE, mass impregnated or oil-filled cables).

In the case of a cable system failure, Nexans will offer its expertise of installing and maintaining submarine cable systems by mobilizing highly-skilled teams to assess the fault and perform any necessary repairs. Nexans is committed to finding the most suitable solution and intervene as quickly as possible, ensuring continuity of power transmission. The areas of operation are located in Northern Europe but can be broadened according to the clients’ needs.

Equinor is a forward-looking company with strong environmental and social values. The approach our two companies take in working together is an example of effective partnership. The teams are dedicated to delivering an assistance service tailored to Equinor and the PRSI pool members’ requirements.

EVP of Generation and Transmission Business Group, Nexans