Plastic is not good for the environment: everyone knows it and everyone makes efforts to avoid it, or at least to sort it better. However, it is still essential in many sectors. Indeed, it remains very important in the design of cables because of its exceptional properties: mechanical, dielectrical, processability, durability…

The problem lies in the poorly managed and uncontrolled plastic waste streams that endanger ecosystems around the world:

- Over 460 million tons of plastics were produced in 2019,

- Up to 50% of plastic waste was sent to landfill,

- Despite current initiatives and efforts, the amount of plastics in the oceans has been estimated to be around 75-199 million tons. According to the Ellen MacArthur Foundation, by 2050 and without action, there will be as much plastic as fish in the sea (1kg for 1kg).

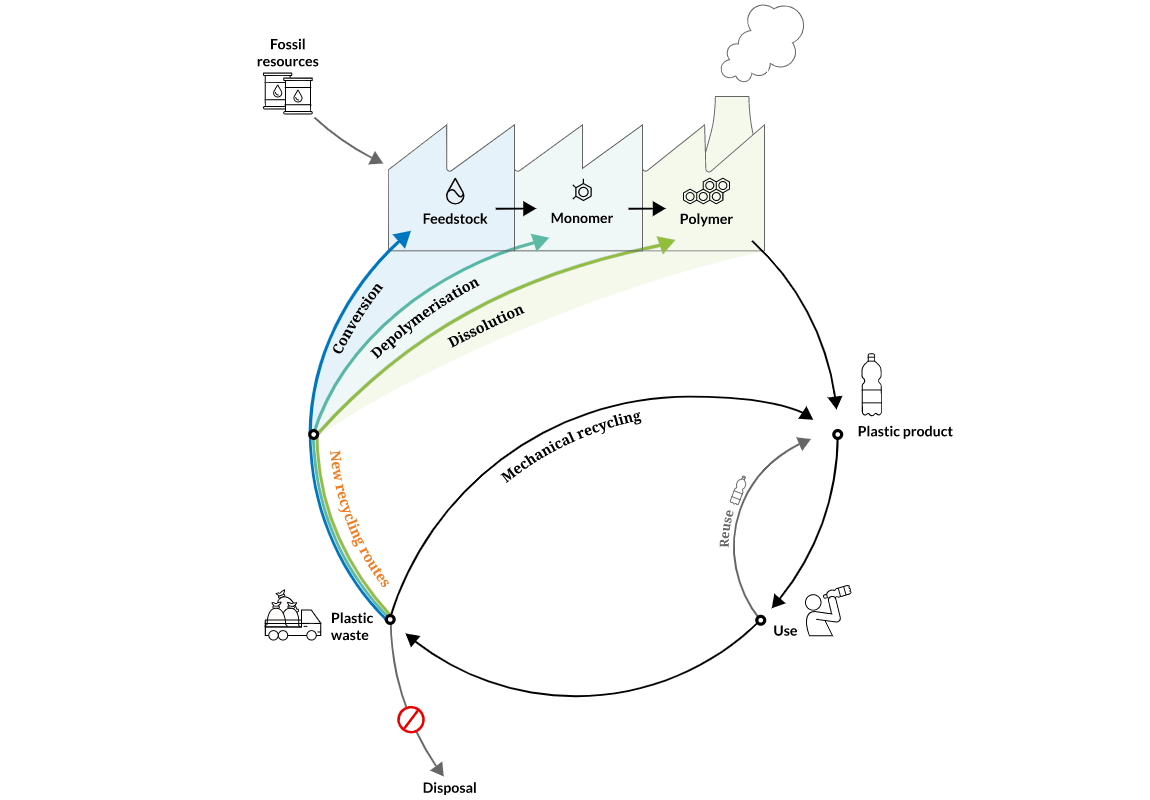

To face the growing volume of plastic produced, used and dumped, industries have to evolve to a fully circular model in which end-of-life plastic products are not discarded but transformed to create value. Innovation, regulation and international collaboration are needed to enable this transition.

In addition to resource management and pollution issues, plastic materials have an impact on greenhouse gases. A kg of polyethylene produced in Europe for plastic manufacturing has a carbon footprint of roughly 1.8 kg of CO2 equivalent.

Plastic material: versatile and unavoidable

Industrial-scale plastics production began in earnest in the 1940s and rapidly increased in the 1950s. More than 8 billion tons of plastics have been produced worldwide since 1950, making it a widely used manufactured material (Geyer et al., 2017).

Plastics offer various benefits such as a high strength-to-weight ratio, and the ability to tailor their physical properties to be hard or soft as needed. This versatility and durability, combined with the low cost of plastic production, is the major reason why plastics are currently used in almost every sector.