HVDC: Powering the future of renewables

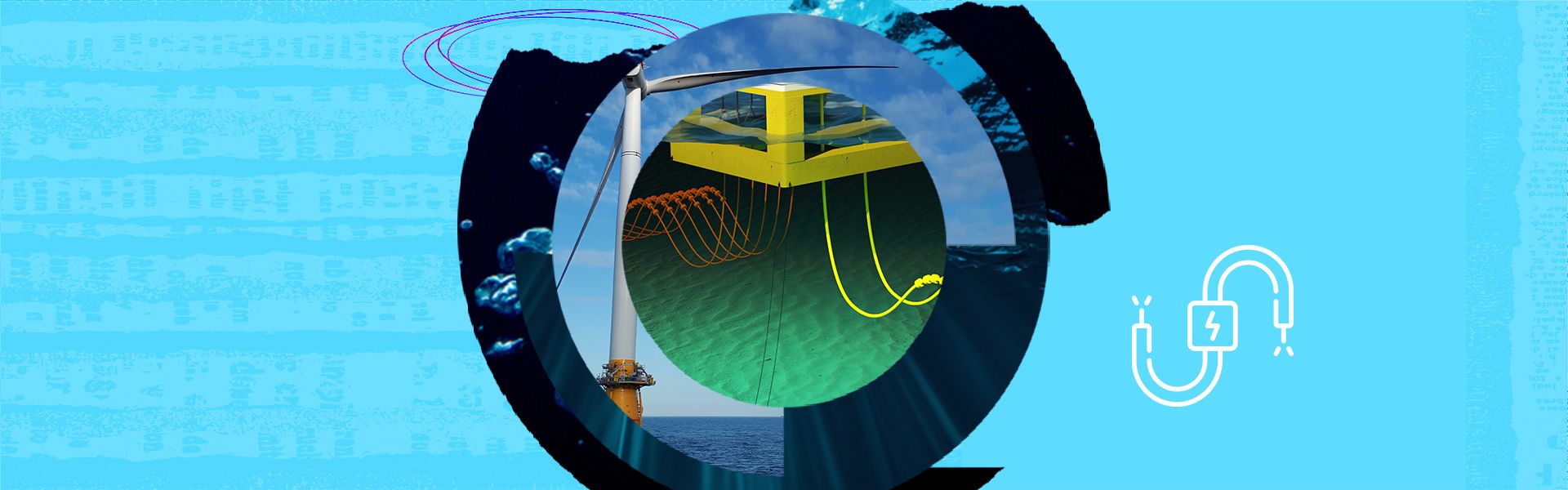

Renewable energy grids today – onshore and offshore – require transmission lines capable of transmitting larger amounts of power over longer distances, more efficiently (lower energy loss), at greater sea depths, and able to withstand harsh environmental conditions.

And it is a key driver in the industry’s shift to 525 kV XLPE HVDC (high-voltage direct current) cable technology for large renewable projects – especially commercial offshore wind farms.

The transition to renewable energy requires a new approach to balancing demand and supply of power. Today, the interconnection of neighboring grids is solving this problem. For example, the grid interconnection between Norway and Germany is a perfect example of balancing complementary energy sources for better grid reliability.

HVDC systems make it all possible. In the future, hybrid interconnections and HVDC meshed grids between countries and offshore wind farms will be a reality.

While up-front investment costs and complexity may favor HVAC, the lower transmission loss levels, ultimate power flow control capability, and black start capability may favor the new HVDC alternative.

According to the January 2024 ENTSO-E report – Offshore Network Development Plans, European offshore network transmission infrastructure needs – 14% of the offshore renewables could be connected via dual-purpose hybrid infrastructure in Europe by 2050.