No interconnections… without cable-laying vessels

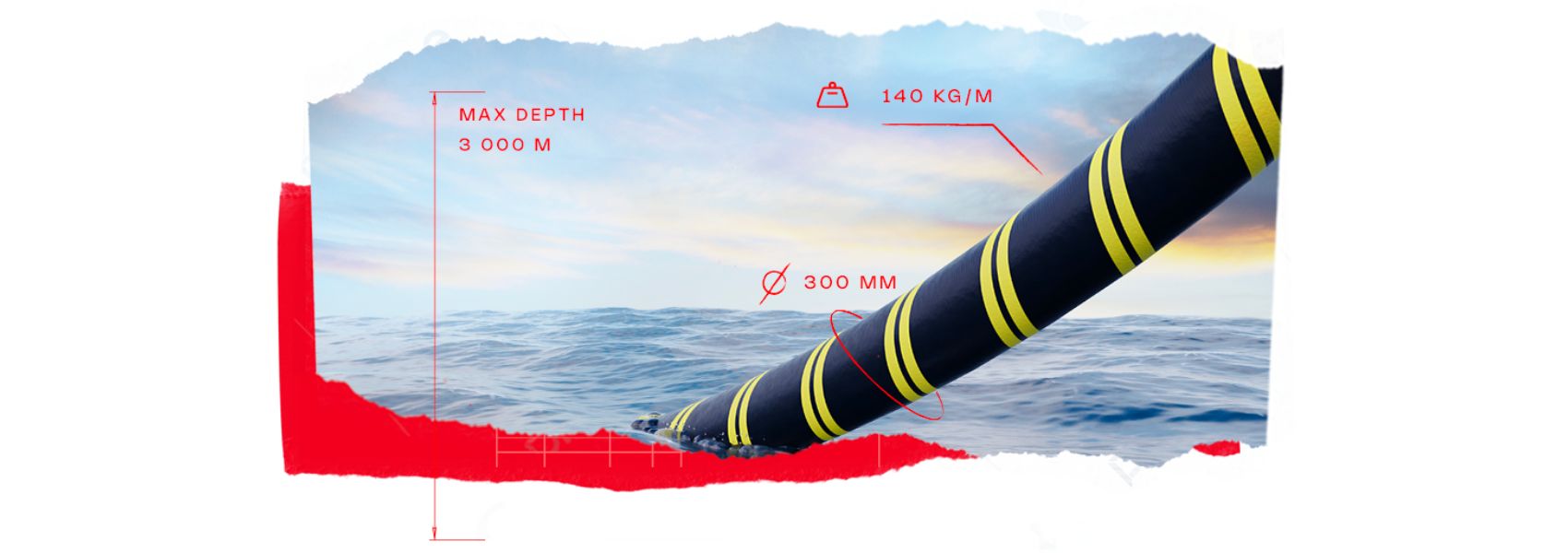

Cable-laying vessels transport the cables and deploy them on the seabed. Measuring over 100m in length in some cases, these steel monsters are high-tech gems and a key component of the interconnection process.

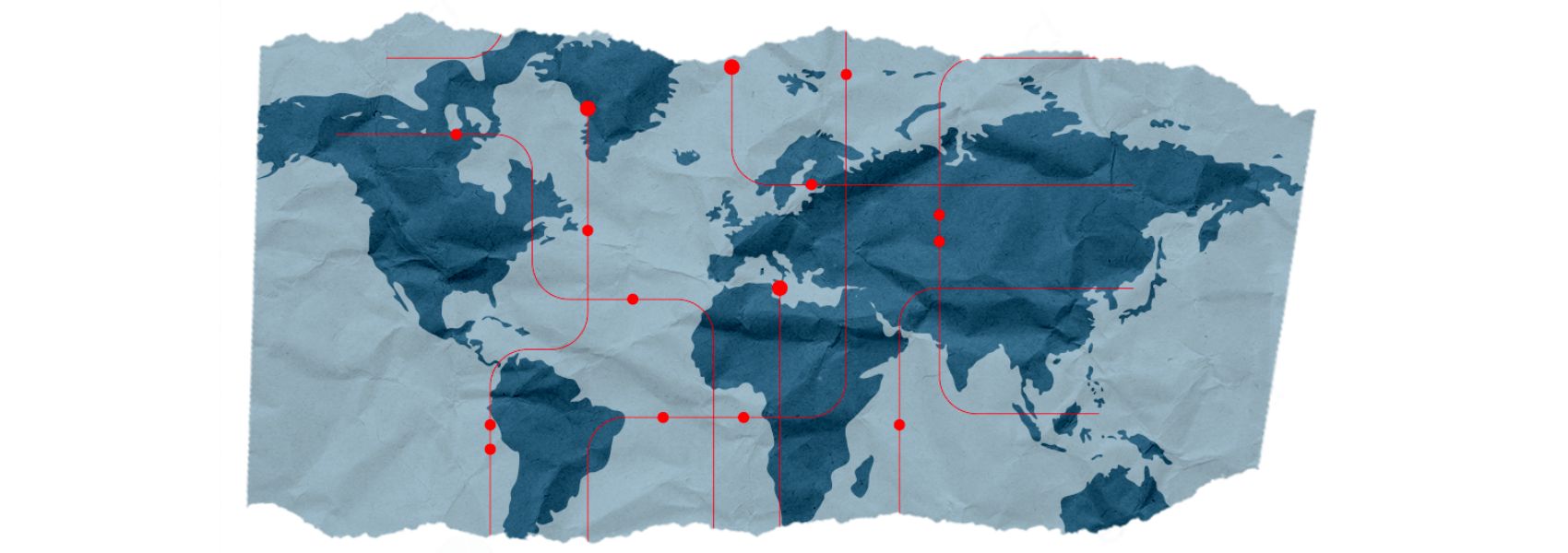

A growing number of new-generation vessels are currently being developed to meet increasing demand for electrification, particularly in Europe and the US.

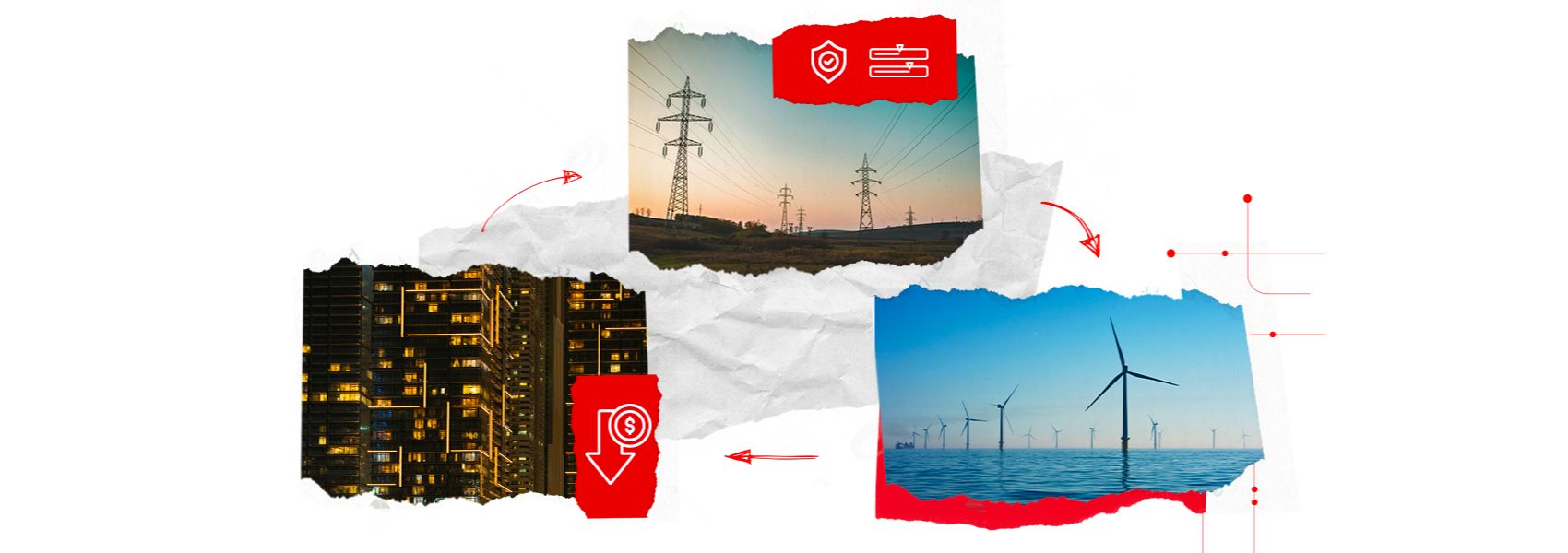

Among the most advanced cable-laying vessels is Aurora. Named after the Roman goddess of the dawn, this giant of the sea is 150m long. A truly exceptional vessel equipped with state-of-the-art technology, Nexans Aurora is capable of laying ultra-high-voltage subsea cables over thousands of kilometers and at abyssal depths. Its role is to connect offshore wind farms to onshore grids, and deliver the power generated by the wind to our homes.

Aurora is Nexans’ second cable-laying vessel. The Group is in the process of adding a third vessel to its fleet: Electra.