- Nexans is investing €4.5 million in its Draveil site to double production capacity of medical cables in response to growing demand.

- The NEWSENSE® micro-cables will be produced by machines entirely designed and manufactured by Nexans.

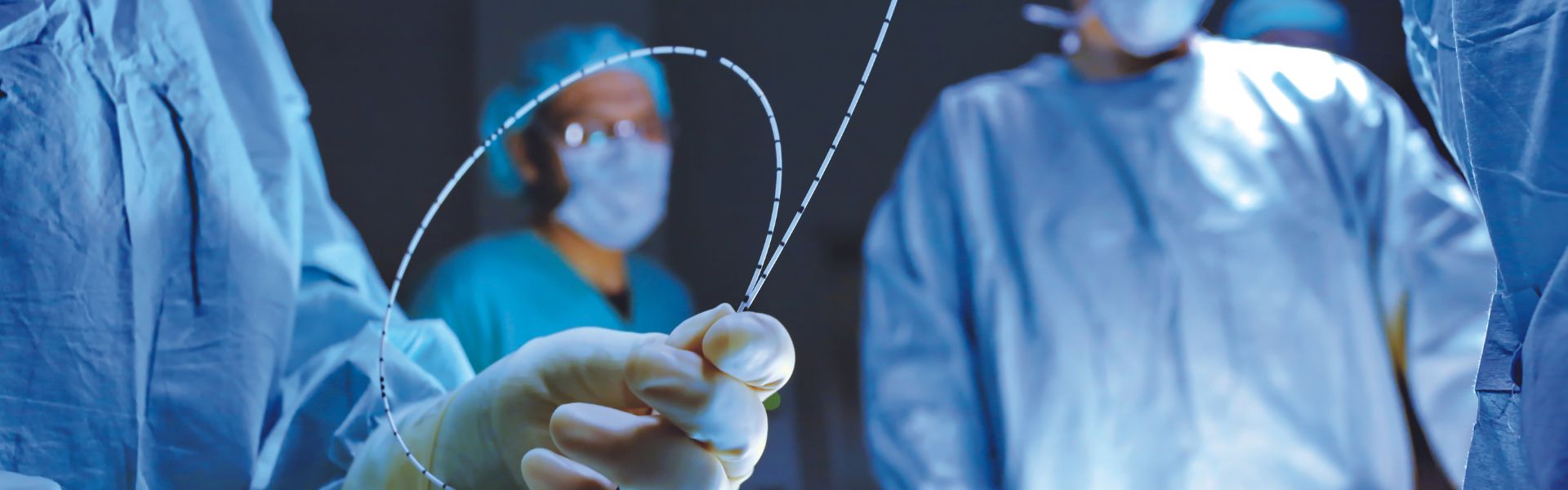

- Building on the expertise and know-how of the Draveil workforce, the Group is developing its cable offering dedicated to minimally invasive surgical technologies, pushing the limits of miniaturization.

A leading designer and manufacturer of cable systems and services, Nexans has announced a €4.5 million investment in its Draveil site outside Paris to double its production capacity for medical cables.

With this investment, Nexans will be able to meet growing demand for medical micro-cables used in invasive surgery, a fast-growing market expected to achieve annual growth of 5% a year over the next five years. These cables are used in particular for transcatheter technology and cardiovascular electrophysiology, as well as for monitoring sensors and endoscopy cable solutions.

Through this investment, Nexans will be able to develop its NEWSENSE range of medical cables in a new workshop expanding the existing facilities at the Draveil site. The Group is reaffirming its commitment to manufacturing in France, particularly for products requiring a high level of expertise, as it is the case in the medical field.

These cables meet the most stringent quality standards and will be manufactured on machines specially designed and built by the engineering teams at Nexans Draveil, as they seek to continuously push back the limits of miniaturization. As these machines do not yet exist on the market, they wil further sharpen the competitive edge of Nexans, allowing it to consolidate its position as an industrial leader in cutting-edge technologies.

Consolidating our medical business is one of the strategic development goals set for our Aerospace & Medical division. Our high-performance cables are particularly well suited to environments demanding compliance with standards ISO 13485 (medical) and EN 9100 (aerospace) for safety and reliability. These particularly demanding standards are recognised by our customers worldwide.

Vice President Aerospace & Medical, Nexans

Delivering the speed and efficiency necessary to stay competitive in this niche market, these machines also meet the highest standards of reliability and quality, with the use of optical control technology to inspect the cables on the production line.

With this investment, Nexans will be able to develop its offering for medical OEMs, a field in which the company has over 30 years’ experience. With a dedicated plant and laboratory, Nexans is setting the standard in the supply of micro-cables for devices used in medical exploration as well as in diagnosis and treatment, greatly improving comfort for both healthcare professionals and patients alike.

With this investment, we are strengthening our position in the medical cable market and taking production capacity to a new level, with our machines and technology we push the limits of miniaturization. We are particularly pleased to be making this investment in Draveil, allowing us to expand with a new workshop dedicated to this market segment.

Executive Vice President Industrial Solutions & Projects, Nexans