Context

RTE France has awarded Nexans a €115 million contract to supply and install power export cables for the Saint Brieuc offshore wind farm. This project, developed by the Ailes Marines Consortium, is a pivotal component of France’s renewable energy strategy, aiming to meet the electricity demands of over 835,000 homes while advancing climate change goals.

Challenges

Started in 2021, the project faces challenges in designing, laying, and maintaining the extensive offshore and onshore cable infrastructure necessary to connect the wind farm to the grid. Additionally, ensuring reliability and efficiency amidst the harsh marine environment presents a significant technical challenge.

496 MW

generated by wind turbines

225 kV

maximum voltage

835,000

homes provided with

energy from this wind farm

67 km

of offshore cables

93 km

of onshore cables

Nexans’ implication

Nexans delivered innovative solutions for both offshore and onshore cable needs. For the submarine cables, Nexans supplied two lengths of 33.5 km 225 kV 3-core cable with an innovative hybrid armoring solution, manufactured in our Halden facility, in Norway. The cable also features a fiber optic element, supplied by our Norway plant in Rognan, for remote health monitoring of the cable link and transmission of information between the offshore wind farm and land base. Cables were installed by Nexans’ own cable-laying vessel, the CS Skagerrak, while the specialized Capjet system has been used to trench the cables into the seabed for protection. Nexans also provides Inspection, Maintenance, and Repair (IMR) services, ensuring the longevity and reliability of the offshore transmission system.

The land cables include 93 km of 225 kV single-core cable, manufactured in our Charleroi facility in Belgium, similar to those provided to RTE by Nexans under the current land cables framework agreement.

This project will be the first offshore connection developed by Nexans for RTE. As such, RTE expects this project to be successful as well as to mark the beginning of a fruitful relationship.

Marine Activities Director, RTE

Nexans’ involvement extends from manufacturing at their facilities in Norway and Belgium to cable laying with their specialized vessel. Laurent Guillaumin, Business Development Director – Offshore Wind Europe, emphasized, ” We are delighted to be working with RTE to provide the grid connection for one of France’s most significant offshore wind projects. The key to this success was our long track record in this sector combined with our ability to offer innovative cable solutions.”

As of spring 2024, the Saint Brieuc offshore wind project is progressing towards commissioning, with Nexans playing a crucial role in ensuring the timely and successful completion of the grid connection. The progressive commissioning marks a significant milestone in France’s renewable energy transition, bringing the nation closer to its ambitious climate targets.

Context

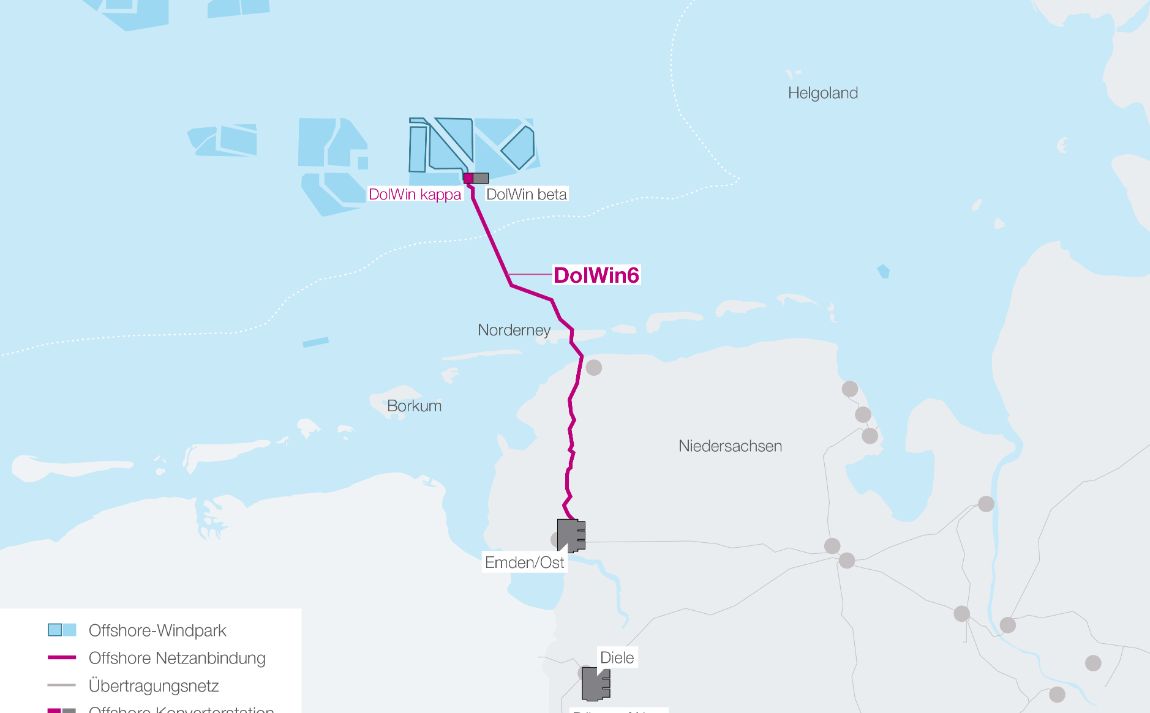

In July 2017, transmission system operator TenneT awarded Nexans the contract to supply and install the cables for the DolWin6 direct-current link. This project aims to transport electricity from the offshore wind farms of North Sea Cluster 3 from the DolWin Kappa HVDC converter station to the Emden/Ost onshore HVDC converter and transformer station. The project involved the installation of two parallel, XLPE-insulated 320 kV DC cables, each measuring 90 km in length, with a maximum output capacity of 900 MW. The project, valued at around 100 million euros, was completed in 2023 and represents one of Nexans Deutschland’s largest projects.

Challenges

The geographical location of the offshore wind farm presented challenges, as the cables must pass through the ecologically sensitive Wadden Sea. Additionally, the cables cross the island of Norderney, necessitating careful installation techniques to protect the environment and wildlife.

Key figures

900MW

Maximum output generated by wind turbines

2x320kV

Maximum voltage of the cables

2x90km

Length of offshore cables

Nexans implication

Nexans was responsible for all stages of the project related to the cable system, including design, manufacture, logistics, and installation. The Group supplied submarine XLPE-insulated 320 kV DC cables, manufactured in Norway, accessories, and installation services. Additionally, Nexans installed a fiber-optic cable for data transfer.

Land cables, produced in Belgium, were installed between Hilgenriedersiel and Emden at a distance of roughly 45 kilometers.

Low-loss high-voltage and ultra-high-voltage cables from Nexans enable grid operators to expand their grids in a way that achieves the best possible results in terms of efficiency and conservation of resources, and thereby to lay the groundwork for the energy supply of the future.

I am delighted that TenneT has awarded us the contract for this important link. With DolWin6, we are responsible for all stages of the project relating to the cable system, including design, manufacture, logistics and installation, and after previous projects such as Beatrice, Italy-Montenegro and NordLink, we once again have the chance to demonstrate our expertise in high-voltage direct-current transmission.

Managing Director, Nexans Deutschland

Context

Equinor awarded Nexans the contract to supply static and dynamic cabling and associated accessories for the world’s first floating wind farm, following a successful demo facilitated by Nexans’ cables which have been in operation since 2009 in Norway. The project aimed to harness the best wind resources by deploying floating turbines further out to sea. The Hywind Scotland Pilot Park, located 30 km off the coast of Aberdeenshire, consists of five wind turbine generators connected through an inter-array cable network, delivering energy back to land in Peterhead, Scotland.

Everything started in 2009 when Equinor’s (former Statoil) “Hywind Pilot”, the first full-scale floating wind turbine, was put into test operation 10 km off the island of Karmøy, Norway. The Hywind Demo project completed eight years of flawless operation. Nexans supplied the 15MW cable that connects the turbine to the island of Karmøy and the transformer station located there.

Challenges

The main challenge was to prove the concept of floating wind power as a viable competitor in the energy market. Despite the successful demo in Norway in 2009, many technological challenges remained to be overcome to demonstrate the cost efficiency and reliability of floating wind farms.

30 MW

floating farm capacity

13.6 km

of XLPE cable

Approximately

20K

Scottish homes powered

Nexans implication

The group played a crucial role in overcoming the challenges by providing specialized cables for both the initial pilot project in Norway and the Hywind Scotland Pilot Park. The Nexans’ specialized facility in Halden designed, manufactured and tested the 13.6 km long 24 kV XLPE-insulated submarine cable, while the Rognan factory supplied the integrated optic fiber element. Additionally, Nexans supplied static and dynamic cabling, ensuring the offshore cable system was tested, sealed off, and delivered ready for installation on site.

Since 2017, the Hywind Scotland wind farm now generates enough energy to power roughly 20,000 homes, showcasing the potential for larger floating wind farms in other areas. The success of this project underscores Nexans’ commitment to driving innovation in the offshore wind industry.

This project is a great example of Nexans pioneering alternative offshore wind design, extending the options for renewable energy generation. The contract establishes Nexans as leaders in offshore wind innovation by designing specialist cables for both the initial pilot project and the Hywind Pilot Park.

Chief Operations Officer and Senior Executive Vice-President, Nexans